Hiring the right system integrator for an automation project can greatly improve the chances of completing the job on time and under budget. And once that first project has been successfully concluded, re-hiring the same integrator for the next job is an easy decision. Unfortunately, selecting an integrator is not so simple the first time out.

|

Hiring the right system integrator for an automation project can greatly improve the chances of completing the job on time and under budget. And once that first project has been successfully concluded, re-hiring the same integrator for the next job is an easy decision.

Unfortunately, selecting an integrator is not so simple the first time out. Not all system integrators are created equal. Some specialize in particular industries; others in specific technologies. Some are simply more competent than others.

The best choice depends upon innumerable details, but the process generally boils down to assessing the project’s staffing requirements, searching for integrators that qualify, and selecting the top candidate.

Needs assessment

Determining the project’s staffing requirements up front will greatly simplify the subsequent search and selection phases. Unfortunately, this phase is also the hardest to quantify since every project is unique. Here are some typical questions to consider:

-

Has a preferred solution already been developed or will the integrator be required to propose one?

-

Will the project require a particular brand of automation equipment?

-

Who will be responsible for specifying and procuring it?

-

Who will be responsible for installing and commissioning it—the integrator, the plant’s in-house engineering staff, an installation subcontractor, or some combination thereof?

-

Who will be managing the project?

-

Will the needs of the plant or the project place limits on the integrator’s geographic location?

-

What time constraints will the integrator be expected to meet?

-

Will the integrator need to have prior experience with any particular applications or technology?

-

Will the integrator need to have prior experience with the kind of process that is to be automated in this project?

Particular care should be exercised when considering prior experience as a selection criterion. Many plant managers decide early on that they only want system integrators who have worked in their industry on similar projects. However, many system integrators are capable of translating their experience from related industries and may even be able to bring new ideas to the project that could lead to a superior solution.

Another common mistake is focusing primarily on price. All too often the plant manager ends up getting what he’s paid for when he hires the lowest bidder. Most experienced system integrators realize that maximizing the client’s return on investment will ultimately prove more valuable than delivering the cheapest possible solution. Some integrators who know the value of their services will even forego bidding on a project if the client indicates that a low price is the primary concern.

Candidate search

Finding system integrators to interview for the job is a relatively straightforward process. Referrals are readily available from most automation suppliers. After all, they have a vested interest in seeing their products installed correctly. Many suppliers maintain formal or informal relationships with system integrators who have received special training and technical support. Other suppliers may be able to provide the required system integration services themselves.

Local distributors may also be able to provide referrals or their own contract engineering services, especially if the project will involve the product lines they represent. Plant managers elsewhere in the industry may be willing to name the integrator who successfully implemented their last automation project, though this approach is not likely to succeed in highly competitive industries where the phone number of a good system integrator is a carefully guarded trade secret.

| Information technology combines with production processes at DAK Americas’ Cooper River site as part of procedures that follow the “Define-Measure-Analyze-Improve-Control” business improvement methodology. |

But arguably the most effective means of identifying suitable candidates are the various online search engines that specialize in system integrators. The most comprehensive of these is Control Engineering ‘s Automation Integrator Guide, listing more than 1,100 automation system integrators by industries and areas served, engineering specialties, product experience, and corporate and professional affiliations. For more information about this guide, see the sidebar ‘Automation system integrators.’

Other options include AutomationTechies, the membership directory of the Control and Information System Integrator Association (CSIA), the ISA Directory, and the Thomas Register.

Candidate selection

The final selection typically involves a review of each candidate’s general credentials and their specific qualifications for the project at hand. Credentials generally fall into four competencies—professional, technological, application, and industry.

Professional competency encompasses the business processes and methodologies required to successfully implement system integration projects. Interviewing the candidates at length, visiting their facilities, and checking references can assess these skills. Alternately, system integrators can prove their professional competency by passing the CSIA’s audit process to achieve the status of Registered Member (see ‘Integrator Registration Aims to Promote Excellence,’ Control Engineering , April 2002).

Technological competency refers to the skills necessary to work with the hardware and software required for the project. Successful integrators maintain a knowledgeable and experienced staff capable of applying products from multiple suppliers. Many automation suppliers will provide special training for their system integrator partners and certify their technical competency on particular products.

Application competency represents the horizontal knowledge that integrators possess, such as process control, batch management, quality engineering, and product tracking. These are skills that apply to a variety of industries. Industry competency comes from executing multiple projects for multiple customers in the same vertical industry. Automation system integrators tend to focus on specific industries, especially food and beverage, chemicals and petrochemicals, material handling, pharmaceuticals, automotive, and water/wastewater.

Selection methodology

When it comes to assessing an integrator’s qualifications relative to the requirements of a particular project, the CSIA can help. They have developed a scoring system based on the Kepner-Tregoe or ‘KT’ decision analysis methodology.

The basic idea is to assign a relative priority to each of the criterion established during the needs assessment then evaluate each candidate accordingly. This can be accomplished in nine steps using the ‘Integrator Evaluation Form’ (see graphic). The individual steps are:

1) State the objective. Compose a short statement describing the intended result of the decision analysis. Example: Select the system integrator best suited for the St. Louis brewery project.

2) List the criteria. Identify the criteria that resulted from the needs assessment. Example: The project requires batch management skills, brewing industry experience, and proximity to St. Louis.

3) Classify the criteria. Distinguish the must-have criteria from the should-have criteria. Example: Candidates should have batch management skills (SH), should have experience in the brewing industry (SH), and must have an office within 100 miles of St. Louis (MH).

4) Prioritize the should-haves. Rate their relative importance on a scale of 1 to 10. Example: Batch management skills are extremely important (9). Brewing industry experience is somewhat important (5).

5) Screen candidates through the must-haves. Determine which candidates meet the must-have criteria. Example: ‘Acme Integrators’ is located 50 miles away (GO). ‘Best Integrators’ is located 90 miles away (GO). ‘Control Integrators’ is located 130 miles away (NO GO).

6) Score the remaining candidates against the should-haves. Assess the performance of each candidate in each area on a scale of 1 to 5. Example: Acme Integrators’ batch management skills are marginal (2), but they have some brewing experience (3). Best Integrators’ batch management skills are outstanding (5), but they have very little brewing experience (1).

7) Compute each candidate’s total score. Weight the individual performance scores according to the criteria’s priority ratings. Example: Acme Integrators’ total is (9 x 2) + (5 x 3) = 33. Best Integrators’ total is (9 x 5) + (5 x 1) = 50

8) Assess the risks . Identify the risks that would result by choosing each candidate and determine if they can be managed. Example: Review Acme Integrators’ design carefully since application experience is marginal. Be prepared to bring Best Integrators up to speed on the unique challenges of successful brewing.

9) Make the final decision . Select the candidate that has the best balance between total score and acceptable, manageable risks. Example: If it’s possible to teach Best Integrators enough brewing skills to get by, select them for the project.

For more about the CSIA’s scoring system and how it can be applied to decisions requiring a more detailed analysis with more complex decision criteria, see ‘Guide for Selecting & Working with a Control Systems Integrator’ available from the CSIA.

Online material

Automation system integrators

Control Engineering ’s Automation Integrator Guide includes a multi-criteria search engine as well as a search-by-name function. When searching for integrators with specific knowledge of systems from particular manufacturers, the search engine scores each specialist by combining their ratings in all of the specified criteria, then displays the results in order of decreasing relevance. A user can widen the search by selecting more criteria in any of seven categories or narrow the search by selecting more categories.

From the list of specialists and other matches, the user can call up an integrator’s profile. Each profile includes the integrator’s contact information and resume in addition to a list of all the criteria they have cited in each of the seven categories.

Note that corporate affiliations include all of the automation suppliers for whom the integrator is a distributor, value-added reseller, or authorized integrator. Professional affiliations include organizations such as the CSIA to which the company or its employees belong.

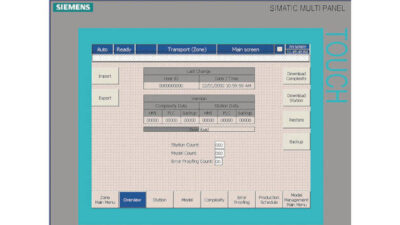

This scorecard can be used to select the most appropriate integrator according to the selection methodology recommended by the CSIA. In this example, Control Integrators is eliminated immediately for failing the “must-have” criterion of proximity to the job site. Acme Integrators outscores Best Integrators in the “should-have” criterion of brewing industry experience, but Best Integrators comes out ahead in batch management skills. Best Integrators wins the overall evaluation since batch management skills have been assigned a higher priority than brewing experience, and the risk of employing an integrator with little brewing experience has been deemed manageable.

For more about the CSIA’s scoring system and how it can be applied to decisions requiring a more detailed analysis with more complex decision criteria, see “Guide for Selecting & Working with a Control Systems Integrator” available from the CSIA.

Automation system integrators

Control Engineering ‘s Automation Integrator Guide includes a multi-criteria search engine as well as a search-by-name function. When searching for integrators with specific knowledge of systems from particular manufacturers, the search engine scores each specialist by combining their ratings in all of the specified criteria, then displays the results in order of decreasing relevance. A user can widen the search by selecting more criteria in any of seven categories or narrow the search by selecting more categories.

From the list of specialists and other matches, the user can call up an integrator’s profile. Each profile includes the integrator’s contact information and resume in addition to a list of all the criteria they have cited in each of the seven categories.

Note that corporate affiliations include all of the automation suppliers for whom the integrator is a distributor, value-added reseller, or authorized integrator. Professional affiliations include organizations such as the CSIA to which the company or its employees belong.